Timber Mats: Did They Cost You Millions?

Timber Mats: Did They Cost You Millions? – was revised on January 5, 2026

-

Many projects lose millions on timber mats because they specify size instead of strength and performance.

-

Matching Eucalyptus timber mats to real loads and soil conditions often cuts freight, replacement, and total cost of ownership.

-

A simple, strength‑based TCO approach helps you choose the right mat thickness instead of over‑ or under‑buying.

Buying timber mats is expensive, and the wrong choices get even more expensive over time. Strength, manufacturing quality, freight, and longevity now matter more than ever to your total cost of ownership on mats.

Why Timber Mats Can Quietly Cost You Millions

Ever found that your timber mats or access mats rotted out early or did not perform as promised? Or that dragline mats were supposed to last two years and barely made it six months? This is not a new problem. About the same time we originally wrote this article, a steel manufacturer posted this one. He didn’t know about Eucalyptus. His points are valid in respect to most mixed hardwood mats.

Those failures are not bad luck. In many cases, they start with how mats are specified and purchased. Most users still specify only size and do not ask for a strength requirement or performance specification. That is what costs millions.

The Question That Protects Your Budget

The question that will save you money is simple: “What is the strength specification?”

Thirty years ago, that question was less urgent. Many mats were made from oak, were true to size, and had fewer defects. You could often get away with specifying only dimensions.

Today, that approach no longer works. Most mats are made of many different species, they are often thinner than advertised, and defects are common. The gap between what you think you are buying and what shows up in the yard is now large enough to move your P&L.

Eucalyptus Timber Mats And Total Cost Of Ownership

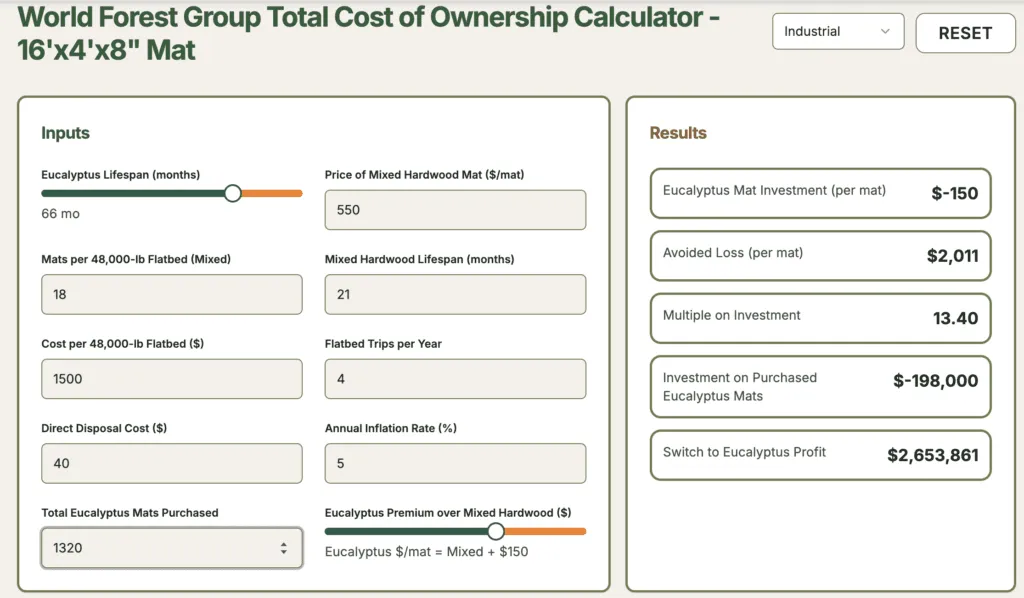

A better way to think about mats is through Total Cost of Ownership. Freight and longevity usually outweigh purchase price, especially when mats must be moved many times and survive tough conditions.

Eucalyptus timber mats are stronger and more standardized than typical mixed hardwood mats. That extra strength lets you consider thinner mats in some applications, which reduces both purchase cost per mat and freight cost per mat. When the mat also lasts longer, the total cost of ownership can be much lower than it looks at first glance.

You can see a rough equivalency between Eucalyptus and mixed hardwood mats. If you are buying 8‑inch mixed hardwood mats today and many are actually under 7.5 inches, there is a good chance a 6‑inch Eucalyptus mat will carry the load and save you money. In some cases, a 5‑inch Eucalyptus mat can also work, depending on your loads and soils.

Right Mat, Right Job: It Depends

Which mats would you choose: 8‑inch mats or 5‑inch mats? The honest answer is that it depends.

The performance specifications for a 48‑inch pipeline with large pipelayers are different from a transmission job with pile drivers and pickups. A 48‑inch pipeline may need an 8‑inch Eucalyptus mat. A transmission line, depending on load and ground conditions, could use a 4‑inch, 5‑inch, or 6‑inch Eucalyptus mat.

The difference between an 8‑inch mat and a 4‑, 5‑, or 6‑inch mat is huge for your budget. You save on purchase price. You save on trucking because thinner, stronger Eucalyptus timber mats allow more mats per truck. You also save on replacement because Eucalyptus can outlast mixed hardwood, which cuts the number of times you buy the same mat capacity again. All of that adds up to a much lower Total Cost of Ownership.

Compared to CLTs, properly designed Eucalyptus access mats offer much higher strength for many applications. That extra strength gives you more flexibility to optimize thickness, freight, and TCO for each job.

Why Strength Specification Matters More Than Ever

The industry has changed over the last 30 years as forest quality has decreased and mat supply and demand have moved out of balance. Species mixes have shifted. Mat thickness is often less than the tag suggests. Quality control varies.

There is still a place for almost every type of mat in the market. The point is not that one mat works everywhere. The point is that knowing mat strength and performance, then matching that to your real loads, lets you spend less for the performance you need.

Even if you never buy one of World Forest Group’s Eucalyptus timber mats, remember to ask for performance specifications every time. Strength, stiffness, allowable deflection, and expected life under your use conditions are what protect your budget, not just board feet or nominal thickness.

Next Steps: Ask Better Questions And Cut TCO

If you start each mat purchase by asking “What is the strength specification?” and “What is the expected life under my loads and soils?”, you will already be ahead of most of the market. You will be able to match performance requirements with the best mat option instead of guessing based on size alone.

For project‑specific help comparing Eucalyptus timber mats to your current mat mix, or to walk through Total Cost of Ownership scenarios, request a quote or contact World Forest Group. A short conversation can help you avoid losing millions on mats on your next program.